When I first started out on my CNC adventure I used Turbo CNC for my controller and it couldn't do Constant Velocity. All I had was exact stop and having heard about how wonderful it was I couldn't wait to change to Mach3. In the meantime while I saved up to buy the CNC magic beans I had to learn how to produce Gcode from my CAD software software that would run smoothly and not try and shake my machine apart. I turned out to be an easy process but I couldn't wait for the promise of Constant velocity.

Finally I upgraded to Mach3 and there were many wonderful things i could now do but to my disappointment the one thing I wanted turned out to be a disappointment. The realization that constant velocity isn't all it is cracked up to be. People might say that I didn't set it up properly and maybe they are right, but set up properly or not it doesn't alter the fact that when it turns on it alters the Gcode file that I spent hours working on. This is a big problem with parts that need to fit together and more trouble than it is worth.

I bet a lot of people use it without realizing what it actually does. How many people spend hours looking for a fault that is distorting their parts and not realize that it could be constant velocity doing exactly what it told and distorting your part. You slow the machine down and the part comes out better because CV behaves differently at different speed. It may even turn off at the lower speed.

The Mach3 CV is very basic with only 3 parameters with which to change how it works but other software have more sophisticated algorithms to govern behavior. This might make it work better but it does not alter the fact the CV changes the tool paths that you spend so much time crafting.

It's time to take back control.

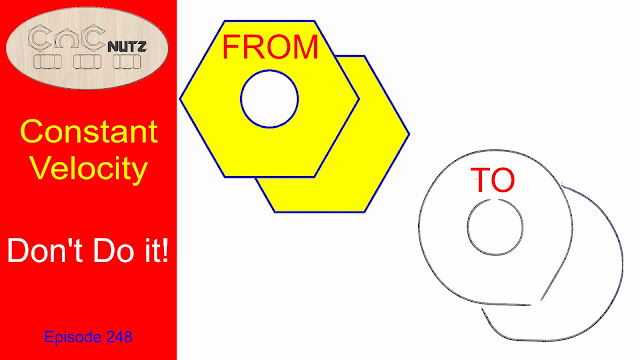

When it comes to parts that need to mesh together like inlays CV is your enemy. Unless it applies the same distortion to the mating parts they will not fit together properly. The same applies to wooden joints and VCarving. If the machine starts making shortcuts all in the name of smoothness and speed then thins are not going to come out as you want.

The Answer

Converting your Cad drawing to circular arcs and using a post processor that outputs arcs will effectively do what the controller does except the conversion process is under your control and done my a much more powerful process instead of being done on the fly using a couple of hundred lines of Gcode to figure out what it thinks you want. If you do your job properly the file will run smoothly and accurately.

When working with inlays and other meshing parts the slight adjustments you make to the drawing can now be applied evenly to both parts so that they will now mesh as you want.

When is an arc not an arc?

You may surprised to learn than not all arcs are the same. Gcode can only describe circular arcs. An oval may look like it is made of 4 arcs in your CAD software but these are bezier curves and cannot be described in Gcode. The result is Gcode made up of hundreds of straight lines making your Gcode file long and run horribly.

In the next episode I will be looking at creating Gcode that runs smoothly eliminating the need to use Constant Velocity if your machine can handle it. Even if it can't and you are forced to use CV it will still improve your machining and reduce the effect that CV has on your project. I will see you then.

Cheers

Peter